Omsky kauchuk

petrochemical production

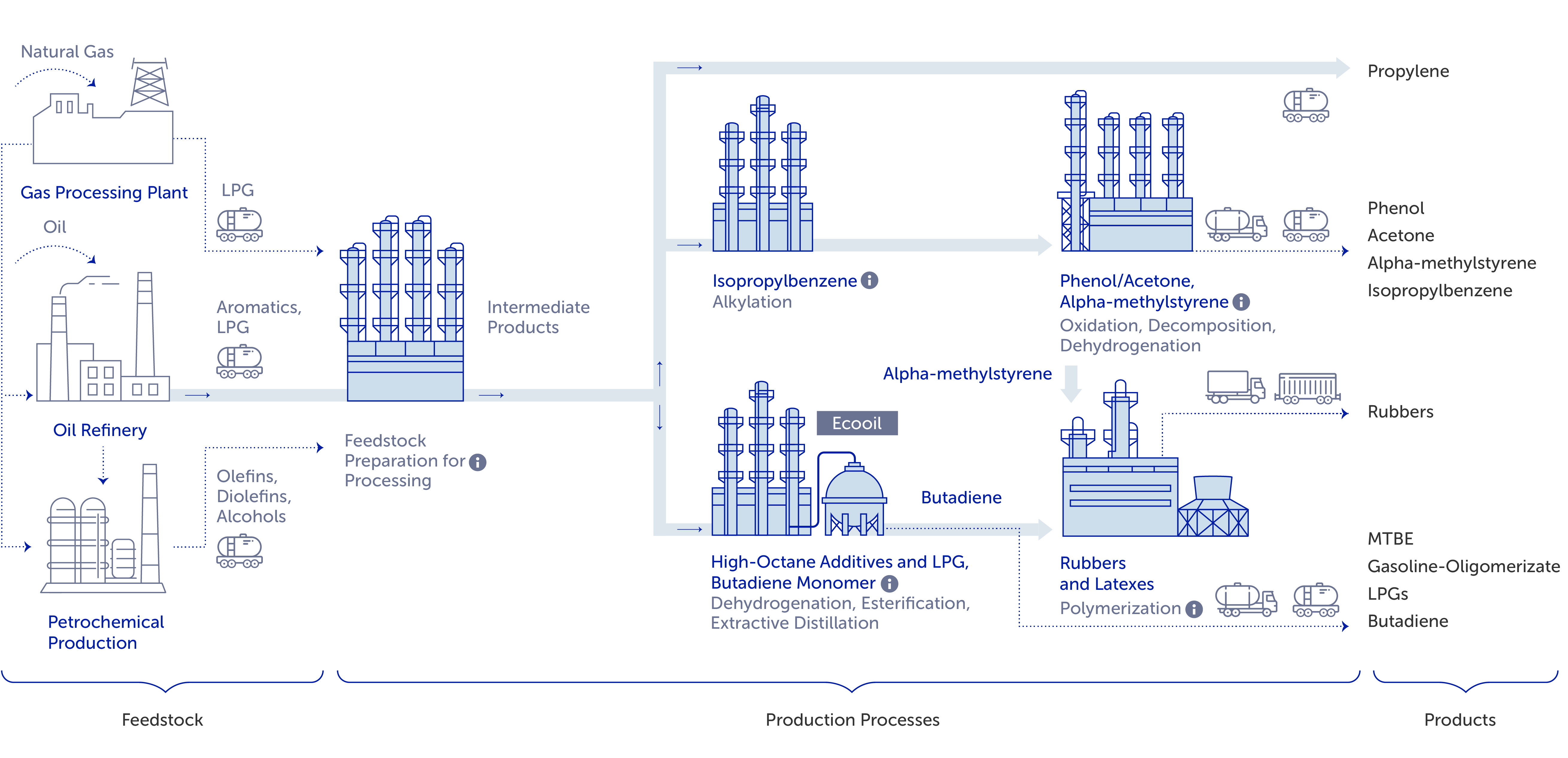

The plant «Omsky kauchuk» is one of the leaders among the Russian synthetic rubber producers.

The plant's birthday is considered to be October 24, 1962, when the first briquette of Omsk rubber was produced. In as little as a year, the enterprise managed to derive divinyl, isopropylbenzene, and the first specification-grade alphamethylstyrene. By 1989, the technological structure of the plant comprised over 30 chemical processes, which enabled using byproducts and waste from one manufacture as raw materials for other manufactures.

Today, Omsky kauchuk is working to further modernize manufactures and solve tasks related to occupational health and safety, the improvement of reliability and safety, as well as process automation. The plant implements brand new projects aimed at deeper hydrocarbon processing and the production of a wide range of import-substituting products, including low-tonnage ones.

Throughout its history, the products of the AO "Omsky kauchuk" have won many prestigious awards, including the international prize for achievements in technology and product quality, the certificate «Leader of the Russian Economy» of the Russian Federation, the Gold Mercury award for the highest sales volumes from the European Association «Partnership for Progress», as well as the diplomas and medals of international exhibitions «Chemistry», «Tires, Industrial Rubber Goods and Rubbers». The plant's products have multiple times won the competition «100 Best Goods of Russia».

In 2006, Omsky kauchuk introduced a management system that conforms to the requirements of the ISO 9001, ISO 14001, and ISO 45001 international standards.

2000

tons of products per day

40

countries consuming

the plant's petrochemical products

3000

employees

AO "Omsky kauchuk"

Intake exceeding:

450 thous. tons

of petrochemical

feedstock per year

Capacity:

160 thous. tons

of isopropylbenzene per year

Sufficient for production:

103 thous. tons

of phenol per year

MTBE per year:

284 thous. tons

The MTBE production plant of the highest capacity

1,5 mln apartments per year

can be supplied with domestic gas through the LPG production

Aggregate capacities of phenol/acetone:

146 thous. tons

per year

The plant's output can be used to produce:

212,8 mln m3

of 22 mm chipboard

110 mln l

of solvent

Capacities:

108 thous. tons

of synthetic butadiene-methylstyrene rubbers per year

17 consuming countries

Ivanilov Sergey Vladimirovich

General Director, AO "Omsky kauchuk"

The AO "Omsky kauchuk" is a large, constantly developing complex with a long history, and its successes are the merit of several generations of employees and managers. My tasks as an industrialist are to maintain and strengthen the team, to contribute to further building market strength of the company, to ensure consistent high quality of products and to achieve even greater reduction of environmental impact through technological processes improving".

Press Center

20 July 2022

"Omsky kauchuk" plant offers import-substituting product to Russian companies

3 February 2022

The AO GC Titan enterprises manufactured more than half a million tons of products in 2021

15 October 2020

AO GC Titan multiplied the synthetic rubbers export volume

Contact Information

AO "Omsky kauchuk"

Asddress:

30, Gubkin Ave., Omsk, 644035, Russia

Telephone Number:

Fax:

E-mail:

info.ok@titan-group.ru